Our products

Micro powders

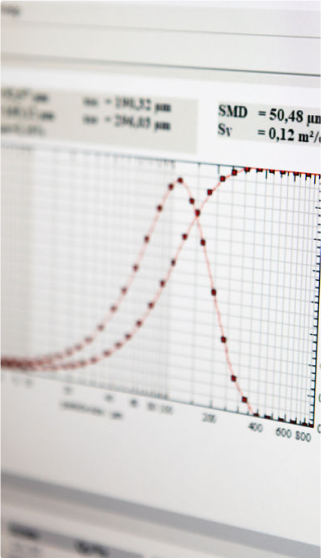

PTFE micro-powders are primarily PTFE particles that provide lubrication and therefore reduce friction between surfaces. However, micro-powders go further than this; it acts as a flame-retardant, makes products resistant against UV and prevents squeaking when two materials touch. Moreover, these lubricants are applied to surfaces where reduced friction, improved abrasion resistance and non-stick properties are desired. They can be used in various applications, such as automotive , marine and the printing industry.

PTFE lubricants characteristics

The main characteristics of PTFE lubricants are:

- Low friction: PTFE has excellent lubricating properties, which helps reduce friction between moving parts, thus minimizing abrasion and extending the lifespan of components.

- Non-stick properties: PTFE’s non-stick nature prevents substances from adhering to surfaces, making it useful in applications where sticking or buildup is a concern.

- Wide application range: PTFE lubricants find use in diverse fields, such as automotive, marine, industrial machinery and more. They are applied to various numbers of other polymers due to their typical characteristics.

- Temperature resistance: PTFE can withstand a wide temperature range, making these lubricants suitable for both high-temperature and low-temperature applications.

Production floor

To meet the diverse needs of our customers, we operate two production units spanning over 2000m². Our facilities house modern, reliable machinery capable of delivering products with precision and efficiency. If you would like to start a collaboration with us, you are always welcome to visit our premises.

Quality & continuity

Thanks to our years of experience, U.P.M. Kunststoffen is able to provide products that align very well with our key customers. Where our customers apply our micro-powders into a diverse range of products, elevating them with the advantages of our lubricants. Through our reliability in terms of delivery and quality, combined with long-standing collaboration, a strong relationship has been built with key individuals within the customer’s organization. These strong and long-lasting relationships enhance our company’s continuity.

U.P.M. Kunststoffen aims to provide its customers with high-quality products, materials suitable for various applications and dependable delivery options that surpass competitors.

By processing PTFE scrap into high-quality micro-powders, U.P.M. Kunststoffen contributes to improving the environment. In doing so, it aims to minimize factors such as energy consumption, CO2 emissions and the release of toxic and/or environmentally harmful substances as much as possible.

Do you have

any questions?

Don’t hesitate to contact us.